Plywood Properties and Advantages for Building - MRS Woodcraft

Every year, the construction industry experiences a growing demand for new building materials, as researchers and experts strive to find alternatives to traditional materials that address common challenges. Plywood has emerged as a highly desirable material due to its many benefits, revolutionizing the wood industry. Today, plywood is in high demand for construction projects, surpassing traditional materials such as natural wood, bricks, and plastic. MRS Plywood, one of the best plywood manufacturers, offers an ideal combination of lightness, strength, and flexibility, making it an excellent choice for various applications. As one of the leading plywood producers and plywood sheet manufacturers in the market, MRS Plywood maintains the highest quality standards to ensure that their products are reliable and durable. As a result, the global plywood market, driven by innovative ply board factories like MRS Plywood, continues to grow at an impressive rate.

What is plywood?

Plywood is a type of engineered wood that is created by stacking several layers of thin wood veneers together. Unlike natural wood, plywood is easily accessible in all regions and is often more cost-effective. This has led to its increased use in the construction industry over the past few decades, as well as in interior design. Plywood is now a popular building material worldwide due to its numerous benefits. Soft, hard, tropical, and decorative plywood are now produced by many companies around the world, with each type serving different purposes. Plywood is used for everything from furniture to constructing the structural framework of a building, making doors and windows, building drywall and partition walls, and creating decorative items. Despite the availability of other composite sheets and panels in the market, plywood remains a preferred choice for experts and woodworkers because of its inherent properties such as strength and stability, ease of working, and affordability.

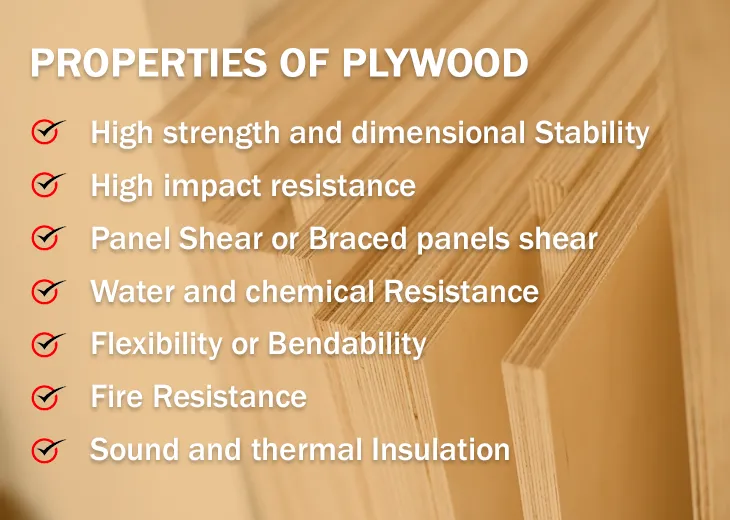

Properties of plywood

1. High strength and dimensional Stability

The structural strength of plywood comes from the timber used in its manufacturing process, in addition to the properties it gains from its laminated construction. The cross-graining technique involves gluing thin plies of wood together at a right angle, which enhances the plywood's resistance to splitting while providing consistent strength and stability. Unlike natural wood, high-quality plywood does not change in size due to fluctuations in moisture content or humidity, meaning it does not expand or contract. This characteristic is the primary advantage of plywood over other materials.

Uses:- Plywood is a cost-effective option for structural applications, including flooring, walls, partitions, formwork, cupboards, shelves, and more, due to its excellent strength and stability.

2. High impact resistance

The cross lamination of plywood panels gives it a high tensile strength by spreading force over a larger area, which reduces tensile stress. This allows plywood to withstand overloading up to twice its designated load.

Uses:- Plywood's high tensile strength is particularly advantageous for flooring and concrete formwork applications. It is well-suited for use in various buildings, including industries with heavy wear, as a result of its durability.

3. Panel Shear or Braced panels shear

Veneer manufacturing plays a crucial role in enhancing the bond ability of wood veneer surfaces through chemical treatment. As a result, plywood panels made from treated veneers exhibit higher shear strength compared to those made from non-treated veneers. By treating veneers, the shear strength of plywood increases to nearly twice that of solid wood, making it an ideal choice for use in wooden structures as bracing for resisting lateral loads.

Uses:-Plywood's excellent strength and stability make it ideal for use as gussets in portal frames, as well as bracing panels and webs in fabricated wooden beams.

4. Water and chemical Resistance

During the manufacturing process of thin plies, a substance is used to treat the veneers which makes plywood highly resistant to water and chemicals. However, it should be noted that plywood has lower water and chemical resistance compared to natural wood.

Uses:-

- Plywood's resistance to water and chemicals makes it a popular choice in chemical industries.

- To enhance its water and chemical resistance, plywood is treated with waterproof glue and other chemicals, resulting in Marine plywood.

- This property makes plywood suitable for various outdoor projects such as garden furniture, decking, porches, and planters, as well as indoor furniture and concrete formwork.

- However, not all types of plywood are water-resistant, and appropriate grades should be used accordingly.

5. Flexibility or Bendability

Plywood stands out from natural wood due to its flexibility or bending ability. Certain types of plywood can be bent easily without breaking or suffering any damage. Plywood can be produced to match every requirement, unlike wood. Additionally, the thickness of plywood can vary from a few millimeters to inches. The number of veneers used in plywood production can range from three to several, increasing the thickness of the plywood sheet. More layers of veneer contribute to greater strength in plywood, while fewer veneers or specifically treated veneers make plywood more flexible or bendable.

Uses:-

- Plywood's ability to flex and bend without breaking or cracking sets it apart from natural wood. This flexibility makes it a preferred material for furniture with curved surfaces.

- Plywood's range of thickness also makes it suitable for various applications such as ceilings, curved formwork, and paneling work.

- In addition to structural uses, plywood's versatility and flexibility make it an ideal choice for manufacturing decorative items and furniture.

6. Fire Resistance

MRS Plywood has the ability to be treated with a fire-resistant chemical coating, which can be combined with non-combustible materials like fibrous cement or plasterboard. The coating on the plywood can resist oxidation, hence decreasing the rate at which fire can spread.

Uses:- This characteristic makes plywood appropriate for application in structures that require fire-resistance.

7. Sound and thermal Insulation

During the production of plywood, thin plies or veneers are bonded together with resin adhesives. This makes it an effective insulator against both heat and sound. Plywood's insulation properties help in reducing heating and cooling expenses significantly.

Uses:- MRS plywood is in high demand for ceilings, flooring, roofing, and wall cladding work in western countries where there is a requirement for high heat resistance.

Benefits of Using Plywood over Other Natural Woods

- Working with natural wood poses a challenge when a large width of wooden member is required, as it cannot be wider than the trunk of the tree. Therefore, joints are necessary for creating a large width wooden member like a door or partition. However, creating joints requires highly skilled workmanship to ensure that the joints do not have visible lines and perform well under different temperatures and humidity levels. In contrast, plywood is available in various standard shapes and sizes, making it easier to use without the need for creating joints.

- Additionally, natural wood is susceptible to moisture, which can cause the joints to either expand or contract. These shortcomings of natural wood can be effectively addressed by using plywood.

- Natural wood has limitations when it comes to thickness as it cannot be obtained beyond a certain point. However, plywood offers a solution to this problem by providing a joint-less surface with a larger area that is not as susceptible to moisture damage as natural wood.

- MRS Plywood is advantageous due to its availability in large sizes, which allows for furniture to be constructed without joints, something that is not possible with natural wood. Additionally, plywood sheets can be up to 8 feet in length, making it a more cost-effective option compared to natural wood.

- The reduced number of joints in plywood compared to wood, leads to faster construction.

- Using plywood requires less skilled labor compared to natural wood.

- Plywood can be effortlessly polished or painted.

- MRS plywood can have a lifespan of up to 10 years or even longer, but its quality may be compromised if it comes into contact with moisture or termites, leading to deterioration. Natural wood has a longer lifespan than plywood.