Plywood plays a significant role both in construction sites and in DIY projects. However, what many people do not realize is that these come in several types. One such type of plywood is known as non-structural plywood.

It differs from other types, so it’s important to understand where and how it can be used. Let’s explore more into what non-structural plywood is and why it is useful.

Understanding Non-Structural Plywood

Non-structural plywood is the most common and one of the versatile types of plywood applied to many interior and decorative works. Contrary to structural plywood, it is not designed to bear significant loads; thus, for applications where strength is not an issue, this would be a perfect suit.

Non-Structural vs. Structural Plywood

Understanding the key differences between non-structural and structural plywood is essential for selecting the right material for your project.

Strength And Load-Bearing Capacity:

- Structural Plywood: It is manufactured to resist heavy loads and also to be supportive in construction projects, including floors, roofs, and walls.

- Non-Structural Plywood: The panels are not that strong and thus cannot bear heavy loads, which is why it is used for lighter purposes such as furniture and non-load-bearing items.

Type Of Glue Used:

- Structural Plywood: Waterproof glue is used to ensure durability and resistance against moisture, which is critical for outdoor and high-moisture environments.

- Non-Structural Plywood: Non-waterproof glue is used and hence its usage inside a building is limited because it is not greatly exposed to moisture.

Durability:

- Structural Plywood: Built to withstand stress, pressure, and environmental factors, making it more durable in harsh conditions.

- Non-Structural Plywood: Less durable due to thinner veneers and weaker glue, making it prone to damage if not used in suitable conditions.

Typical Applications:

- Structural Plywood: Commonly used in building construction, such as in subflooring, roofing, wall sheathing, and other structural components.

- Non-Structural Plywood: Often used for making furniture, cabinets, wall paneling, and other decorative projects where structural integrity is not a concern.

Cost:

- Structural Plywood: Generally more expensive due to its enhanced strength, durability, and the use of higher-quality materials.

- Non-structural plywood: Usually more affordable, making it a cost-effective choice for projects where high strength is not necessary.

Weight:

- Structural Plywood: Typically heavier due to the denser and thicker layers of wood, which contribute to its strength.

- Non-Structural Plywood: Lighter and easier to handle, making it a popular choice for DIY projects and lightweight furniture.

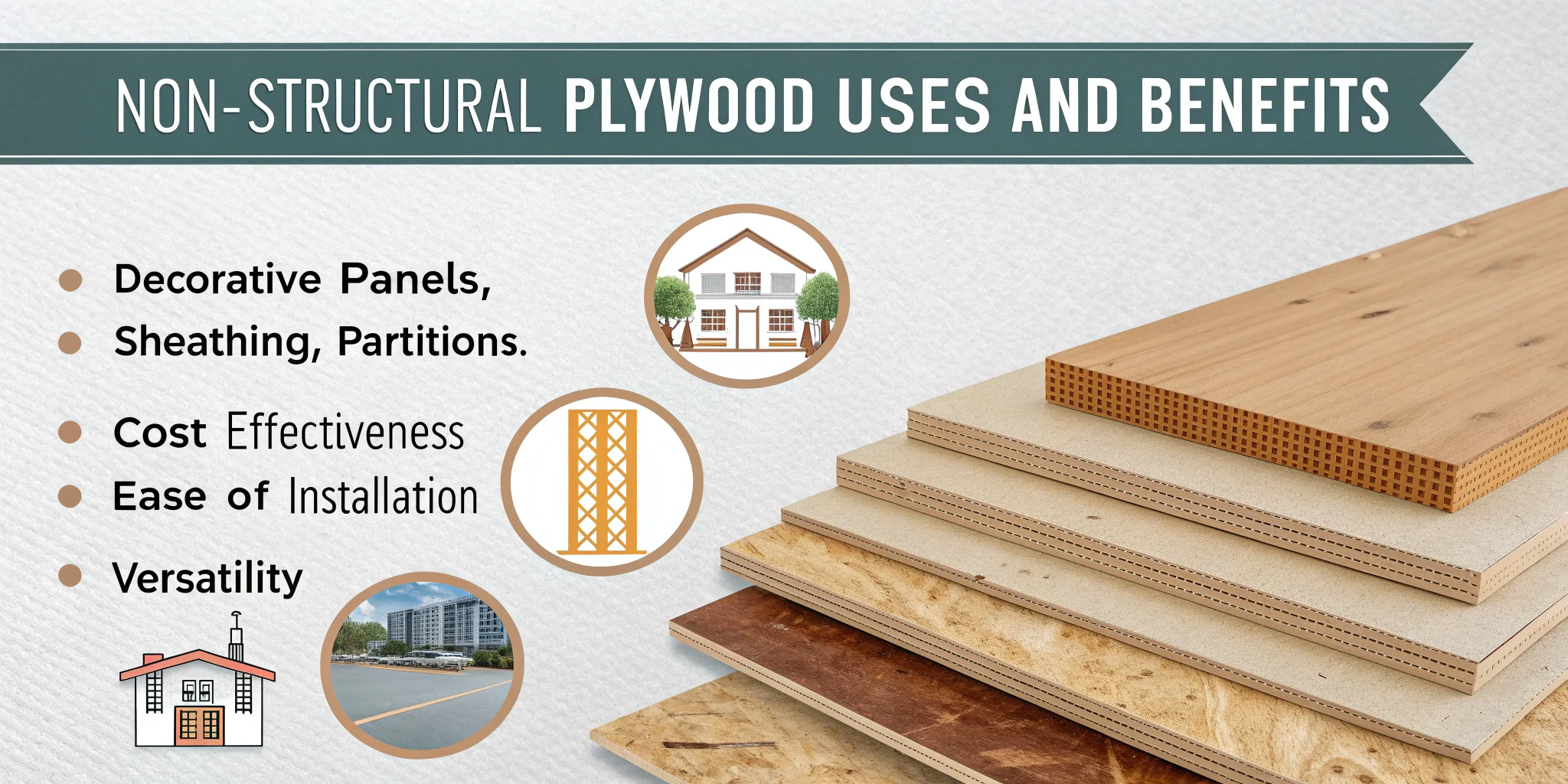

Common Uses For Non-Structural Plywood

Non-structural plywood serves well in various indoor applications where heavy load-bearing is not required.

- Furniture Making: Ideal for constructing cabinets, shelves, and lightweight furniture pieces.

- Wall Paneling: Used for decorative wall coverings that don’t need to bear weight.

- Base for Laminates: Provides a smooth, flat surface for applying laminates or veneers in furniture making.

- DIY Projects: Popular for small home projects due to its ease of use and lightweight nature.

- Decorative Elements: Perfect for creating artistic or decorative features where structural strength isn’t necessary.

Advantages Of Non-Structural Plywood

Non-structural plywood offers several benefits, especially for projects that don’t require heavy-duty materials.

- Cost-Effective: Generally less expensive than structural plywood, making it budget-friendly.

- Lightweight: Easier to handle and transport compared to heavier structural plywood.

- Easy to Work With: Can be cut with basic tools, making it accessible for beginners and DIY enthusiasts.

- Smooth Surface: Ideal for painting or applying veneers, allowing for a variety of finishes.

- Versatile Applications: Suitable for various indoor projects where strength is not a priority.

Limitations Of Non-Structural Plywood

Despite its advantages, non-structural plywood has some important limitations to consider.

- Lower Strength: Not suitable for load-bearing or structural applications.

- Not Waterproof: The glue used is not waterproof, making it unsuitable for outdoor use or in wet environments.

- Limited Durability: Prone to warping or breaking if exposed to moisture.

- Restricted Use: This should only be used in projects where its lower strength won’t compromise the final product.

- Susceptible to Damage: Can be easily damaged if not handled with care, especially in high-traffic or rough-use areas.

Maintenance And Care Tips For Non-Structural Plywood

Maintaining non-structural plywood involves several systematic steps to ensure its durability and appearance:

- Keep it Dry: Moisture is the primary enemy of non-structural plywood. To prevent warping, swelling, or mold growth, always keep the plywood dry. Avoid exposing it to water or high-humidity areas without proper protection.

- Regular Cleaning: Clean the surface regularly using a soft, damp cloth to remove dust and dirt. Steer clear of harsh chemicals, as they can damage the finish and weaken the plywood over time.

- Apply a Sealant: In areas prone to moisture, such as kitchens or bathrooms, consider applying a water-resistant sealant. This extra layer of protection will help prevent water damage and extend the plywood’s life.

- Inspect for Damage: Periodically check the plywood for any signs of wear or damage, like peeling edges, cracks, or surface scratches. Address these issues immediately to avoid further deterioration.

- Avoid Heavy Loads: Since non-structural plywood isn’t designed to bear heavy loads, ensure it’s used appropriately. Avoid placing heavy objects on it to maintain its structural integrity.

Choosing The Right Plywood For Your Project

When choosing plywood for a project, it’s important to think about what the plywood will be used for. If you need something strong that can support weight, structural plywood is the way to go. But if you’re building furniture or doing a small DIY project, non-structural plywood might be the best choice. Always make sure to choose the right type of plywood for your specific needs.

Conclusion

In conclusion, non-structural plywood is a versatile and affordable material that is perfect for a variety of projects. Whether you’re building furniture, creating decorative pieces, or working on a DIY project, non-structural plywood offers an easy-to-use and cost-effective option. Just remember to use it in the right situations and avoid areas where it might get wet or need to support heavy loads.

Frequently Asked Questions (FAQs)

What Is Non-structural Plywood Used For?

Non-structural plywood is commonly used for making furniture, cabinets, and decorative wall paneling. It’s great for projects where strength is not the main concern.

Can non-structural plywood be used outdoors?

No, non-structural plywood should not be used outdoors. The glue used in non-structural plywood is not waterproof, so it can break apart if it gets wet.

Is Non-structural Plywood Cheaper Than Structural Plywood?

Yes, non-structural plywood is usually less expensive than structural plywood. This makes it a good choice for budget-friendly projects.

Can You Paint Non-structural Plywood?

Yes, you can paint non-structural plywood. It has a smooth surface that is perfect for painting or adding a decorative veneer.

What tools are needed to cut non-structural plywood?

Non-structural plywood can be cut with basic tools such as a handsaw or jigsaw. Because it is lighter and thinner, it is easier to cut than structural plywood.

How Can You Tell The Difference Between Structural And Non-structural Plywood?

The easiest way to tell the difference will be the label or stamp that’s on the plywood. Structural plywood will usually have a stamp that says it is for load-carrying purposes. Non-structural plywood will not bear this stamp.