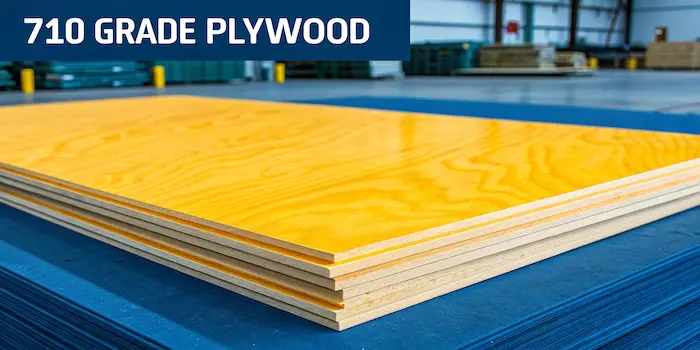

710 Grade Plywood is a high-quality waterproof plywood used in various applications. It is strong, durable, and resistant to moisture. This type of plywood is ideal for furniture, construction, and marine use. The term c710 Grade Plywood is also used to describe this material in some regions.

Features of 710 Grade Plywood

This plywood is boiling waterproof (BWP) and can withstand 72 hours in boiling water without damage, making it ideal for moisture-prone areas.Like this, it has several features which are discussed below

1. Waterproof and Durable

One of the most significant advantages of 710 Grade Plywood is its waterproof nature. It is boiling water-resistant (BWP) and can withstand continuous exposure to water for up to 72 hours without any damage. This makes it ideal for places with high moisture levels, such as kitchens, bathrooms, and marine applications.

2. High Strength and Load-Bearing Capacity

Manufacturers use selected hardwood veneers to create c710 Grade Plywood, ensuring its high strength. The layers are bonded with phenol formaldehyde (PF) resin, making the plywood strong enough to support heavy loads.

3. Termite and Borer Resistant

Termites and borers are a major concern for wooden products, but 710 Grade Plywood is treated with chemical preservatives that provide high resistance against these pests. This treatment not only enhances its lifespan but also reduces the maintenance required over time. It is an excellent choice for areas prone to termite infestations.

4. Smooth Surface Finish

The surface of c710 Grade Plywood is smooth and uniform, making it easy to polish, paint, or laminate. This smooth texture enhances the plywood’s aesthetic appeal, making it suitable for high-end furniture, cabinets, and decorative applications.

5. High Durability in Harsh Conditions

This plywood is built to withstand extreme environmental conditions, including high humidity, temperature fluctuations, and heavy pressure. Whether used indoors or outdoors, maintains its structural integrity, making it a reliable material for construction and industrial use.

6. Resistant to Cracks and Splitting

Another notable feature of this plywood is its resistance to cracking and splitting. The multiple layers of hardwood veneers ensure uniform strength, preventing cracks even under high stress or impact. This feature makes it ideal for doors, partitions, and other structural applications.

7. Fire Retardant Properties (Optional)

Some manufacturers offer a fire-retardant variant of Plywood. This plywood is treated with fire-resistant chemicals, making it safer for use in commercial spaces, kitchens, and public buildings. While not all 710 plywood is fire-retardant, it is available as an upgraded option.

Uses of 710 Grade Plywood

710 grade plywood is primarily used for applications where high moisture resistance is needed, such as kitchen cabinets, bathroom vanities, outdoor furniture, boat building, and any other construction elements exposed to extreme weather conditions due to its excellent waterproof qualities.

1. Marine and Boat Building

One of the primary applications of 710 Grade Plywood is in boat and shipbuilding. Due to its waterproof properties, it can withstand constant exposure to water without rotting or losing its strength. This makes it ideal for boat decks, hulls, and marine furniture.

2. Kitchen and Bathroom Cabinets

In areas with high moisture and humidity, such as kitchens and bathrooms, ordinary plywood tends to swell and lose durability. 710 Grade Plywood, being boiling waterproof (BWP), prevents moisture absorption and ensures long-lasting performance in such environments. It is commonly used for making kitchen cabinets, bathroom vanities, and sink storage units.

3. Furniture Manufacturing

Furniture manufacturers prefer c710 Grade Plywood for sofas, wardrobes, beds, tables, and chairs because of its high strength and termite resistance. It can support heavy loads and provides a sturdy, long-lasting structure for all types of furniture.

4. Wall Paneling and Decorative Applications

Thanks to its smooth surface and easy polishability, this plywood is widely used in wall paneling, ceilings, and interior décor. It provides an elegant, modern look to interiors, making it a favorite choice for luxury homes, offices, and hotels. Additionally, its resistance to moisture and termites ensures that decorative applications last for years.

5. Outdoor Applications

Because of its durability and resistance to extreme weather, 710 Grade Plywood is commonly used in outdoor furniture, garden benches, and signboards. It does not degrade quickly when exposed to sun, rain, or temperature fluctuations, making it ideal for external structures.

6. Industrial and Construction Uses

Industries and construction sites widely use c710 Grade Plywood for making concrete shuttering, scaffolding, and formwork. Since it can bear heavy loads and extreme pressure, it is perfect for supporting concrete structures during construction.

7. Railway and Transport Industry

Another significant application of 710 Grade Plywood is in railway coaches, buses, and trucks. It is used to make flooring, partitions, and paneling due to its strength, lightweight nature, and resistance to wear and tear.

8. Fire-Resistant Applications

Some industries and commercial buildings require fire-resistant materials for added safety. The fire-retardant version of Plywood is used in public spaces, auditoriums, and hotels where fire safety is a priority.

How is 710 Grade Plywood Manufactured?

- Selection of Hardwood Veneers: Manufacturers use premium hardwood logs to ensure durability.

- Bonding with Phenol Formaldehyde Resin: This ensures strong adhesion and waterproof properties.

- Pressing Under High Temperature: The plywood is hot-pressed at high temperatures and pressure to strengthen its layers.

- Chemical Treatment: It undergoes anti-termite and anti-borer treatments to enhance its lifespan.

- Quality Testing: Each sheet is tested for moisture resistance, strength, and durability before reaching the market.

How to Identify Original 710 Grade Plywood?

- Check for ISI Mark: Original plywood should have ISI 710 certification for authenticity.

- Waterproof Test: Submerge a sample in boiling water for 72 hours to check for delamination.

- Look for Branding and Labels: Reputed brands print their logo and specifications on every sheet.

- Check the Surface: The surface should be smooth and free from cracks or warping.

Difference Between 710 Grade Plywood and 303 Grade Plywood

| Feature | 710 Grade Plywood | 303 Grade Plywood |

|---|---|---|

| Waterproof | Boiling Waterproof | Moisture Resistant |

| Resin Used | Phenol Formaldehyde | Urea Formaldehyde |

| Durability | High | Moderate |

| Uses | Marine, Construction, Outdoor | Indoor Furniture, Cabinets |

Conclusion

710 Grade Plywood is a top-quality, waterproof plywood ideal for wet and harsh environments. Whether you are building boats, furniture, or outdoor structures, this plywood ensures durability and strength. Always check for ISI certification before buying Plywood to ensure authenticity.

Frequently Asked Questions? (FAQs)

What Is The Main Difference Between 710 And 303 Grade Plywood?

710 Grade Plywood is boiling waterproof, while 303 Grade Plywood is only moisture resistant.

Can I Use 710 Grade Plywood For Outdoor Furniture?

Yes, it is suitable for outdoor furniture due to its high moisture resistance.

Is c710 Grade Plywood Different From 710 Grade Plywood?

No, c710 Grade Plywood is another name for 710 Grade Plywood, used in some regions.

How To Check If Plywood Is Really Waterproof?

You can perform a boiling water test by submerging it in hot water for 72 hours.

Which Resin Is Used In 710 Grade Plywood?

Manufacturers use phenol formaldehyde resin to make it waterproof.