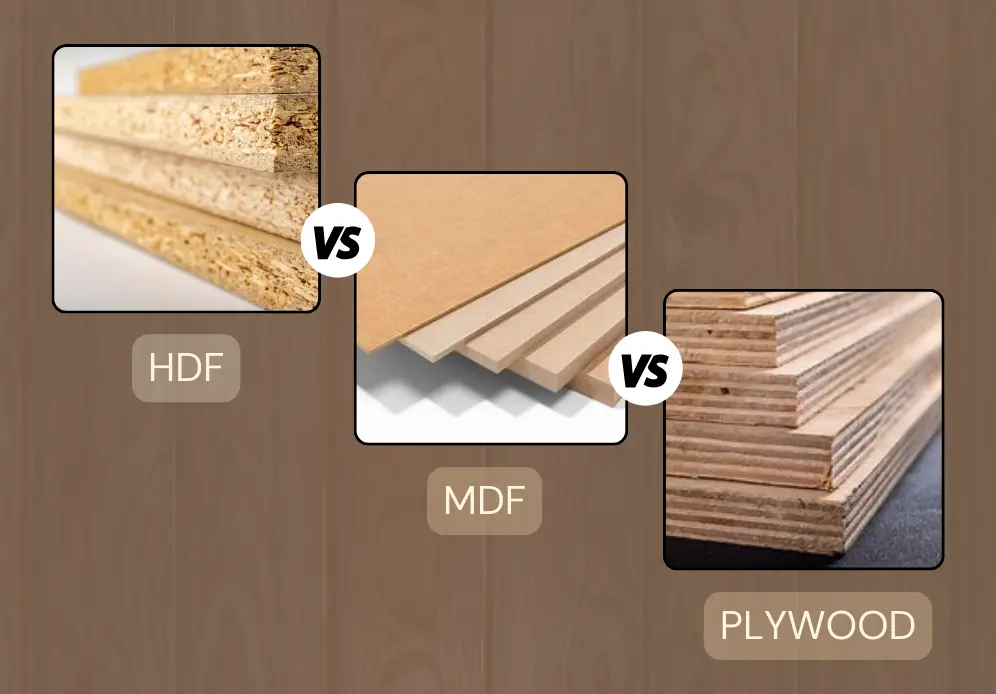

When working on furniture, cabinetry, or home improvement projects, the choice of material is critical. Among the most common options are HDF, MDF, and plywood. In the debate of HDF vs MDF vs Plywood, each material offers unique properties and advantages.

Knowing their differences can help you make the right decision for your project. In this guide, we’ll explore the strengths, weaknesses, and applications of HDF, MDF, and plywood.

What Is HDF And How Is It Used In Various Applications?

HDF stands for High-Density Fiberboard. It is an engineered wood product made from compressed wood fibers. The high compression and heat applied during its production give HDF a dense, hard, and durable structure.

- Used in furniture manufacturing, providing a smooth surface ideal for lamination and painting.

- Applied in flooring, HDF serves as a core material in laminate flooring due to its moisture resistance and strength.

- Ideal for doors and panels, HDF is often used in flush doors and cabinetry for its uniform, smooth finish

What Is MDF And How Is It Used In Various Applications?

MDF, or Medium-Density Fiberboard, is similar to HDF but less dense. It is also made from wood fibers compressed with heat and resin. MDF is softer than HDF and easier to work with, making it popular for furniture and interior projects requiring intricate designs or carving.

- Used in furniture production, MDF is commonly found in cabinets, shelving, and flat-pack furniture due to its affordability and versatility.

- Preferred for interior doors and moldings, providing a cost-effective alternative to solid wood with a sleek finish.

- Applied in speaker enclosures, MDF is popular in acoustics for its density and ability to dampen vibrations.

What Is Plywood And How Is It Used In Various Applications?

Plywood is an engineered wood product made by gluing together multiple layers of thin wood veneers. These layers are arranged in alternating grain directions, giving plywood strength and durability.

- Used in furniture making, plywood is favored for cabinets, tables, and chairs due to its stability and smooth finish.

- Applied in construction, it’s commonly used in flooring, walls, and roofing for its ability to bear heavy loads.

- Ideal for interior and exterior doors, plywood offers flexibility in design and finish while providing robustness for both residential and commercial spaces.

HDF vs MDF vs Plywood: Key Differences

To understand HDF vs MDF vs Plywood, it’s important to examine them based on composition, strength and durability, cost, moist resistance, and more.

1. Composition

- HDF: Composed of finely compressed wood fibers.

- MDF: Made from wood fibers but less compressed than HDF.

- Plywood: Composed of layers of wood veneers glued together.

This basic distinction affects their density, weight, and strength.

2. Strength and Durability

- HDF: Stronger and denser than MDF but not as robust as plywood. Suitable for applications requiring a hard surface but not structural strength.

- MDF: Softer and less durable than HDF or plywood, making it ideal for intricate furniture pieces.

- Plywood: The strongest among the three, ideal for structural applications and heavy-duty furniture.

3. Cost

- HDF: Generally more expensive than MDF but cheaper than plywood.

- MDF: The most affordable option, ideal for budget projects.

- Plywood: The most expensive due to the quality of natural wood used in its layers.

4. Moisture Resistance

- HDF: Low moisture resistance, making it unsuitable for wet areas like bathrooms or kitchens.

- MDF: Less moisture-resistant than HDF but can swell if exposed to water.

- Plywood: Offers the best moisture resistance, especially marine-grade plywood, which is treated for high humidity or wet environments.

5. Weight

- HDF: Heavier due to its density.

- MDF: Lighter than HDF, making it easier to work with in certain applications.

- Plywood: Lighter than both HDF and MDF, despite its strength.

6. Surface Finish

- HDF: Provides a smooth, consistent surface that’s perfect for painting or laminating.

- MDF: Also smooth, ideal for painting and decorative finishes.

- Plywood: Natural wood grain provides a rustic or finished look, though it may require additional sanding or staining.

7. Workability

- HDF: Hard to cut or drill due to its density.

- MDF: Easier to work with, making it perfect for furniture requiring intricate designs.

- Plywood: Easy to work with but holds nails and screws better than HDF or MDF.

Applications: Where To Use HDF, MDF, And Plywood?

Understanding where to use HDF, MDF, and plywood will help you make the best material choice for your project.

1. Furniture

- HDF: Ideal for indoor furniture with flat, smooth surfaces like shelves, cabinets, or wardrobes.

- MDF: Best for decorative furniture requiring intricate designs or curves.

- Plywood: Excellent for heavy-duty furniture like tables, chairs, and load-bearing pieces.

2. Flooring

- HDF: Commonly used in laminate flooring due to its hardness.

- MDF: Rarely used in flooring because of its lower durability.

- Plywood: Used as a subflooring material because of its strength and resilience.

3. Cabinetry

- HDF: Perfect for cabinet doors and panels, providing a smooth finish for painting or laminates.

- MDF: Great for decorative cabinet elements or interiors.

- Plywood: Ideal for the structural framework of cabinets due to its strength.

4. Wall Paneling

- HDF: Suitable for smooth wall panels and decorative elements.

- MDF: Often used for decorative wall panels or wainscoting.

- Plywood: Used in both decorative and structural wall paneling, especially in areas with moisture.

Pros and Cons of HDF, MDF, And Plywood

HDF: Denser and more durable than MDF but can be heavy and less flexible.

MDF: Smooth surface ideal for painting, but less durable and susceptible to moisture.

Plywood: Strong and moisture-resistant with good structural integrity, but can be more expensive and harder to finish.

HDF vs MDF vs Plywood: Which One Should You Choose?

Choosing between HDF vs MDF vs Plywood depends on the requirements of your project. If you need a material with a smooth surface and durability for indoor furniture, HDF is a great option.

MDF is perfect for projects requiring detailed designs or curves, but it’s not the best for high-moisture areas. Plywood is ideal for strength, durability, and moisture resistance, making it suitable for structural and heavy-duty projects.

When deciding, consider your budget, the environment where the material will be used, and the load it will bear.

Conclusion

In the debate of HDF vs MDF vs Plywood, there is no one-size-fits-all answer. Each material has unique strengths and weaknesses that make them suited for specific projects. HDF offers a smooth, hard surface, making it great for decorative indoor pieces.

MDF is perfect for intricate designs and affordable furniture, while plywood provides the strength and durability needed for structural applications.

By understanding the properties of HDF, MDF, and plywood, you can confidently choose the right material for your next project, ensuring durability, aesthetic appeal, and cost-effectiveness.

Frequently Asked Questions (FAQs)

Find answers to common questions about HDF vs MDF vs Plywood including materials, benefits, maintenance, customization options, and comparisons between each other.

Which Material Is Strongest: HDF, MDF, Or Plywood?

Plywood is the strongest due to its layered structure, making it suitable for structural applications.

Can HDF, MDF, Or Plywood Be Used Outdoors?

Plywood, especially marine grade, can be used outdoors. HDF and MDF are not recommended due to their poor moisture resistance.

Which Material Is Most Cost-Effective?

MDF is the most affordable, making it ideal for budget-conscious projects.

Can You Paint HDF, MDF, And Plywood?

Yes, all three materials can be painted, but HDF and MDF provide a smoother surface for painting.

Which Is Better For Cabinets: HDF, MDF, Or Plywood?

Plywood is better for cabinet structure, while HDF or MDF can be used for cabinet doors or decorative panels.