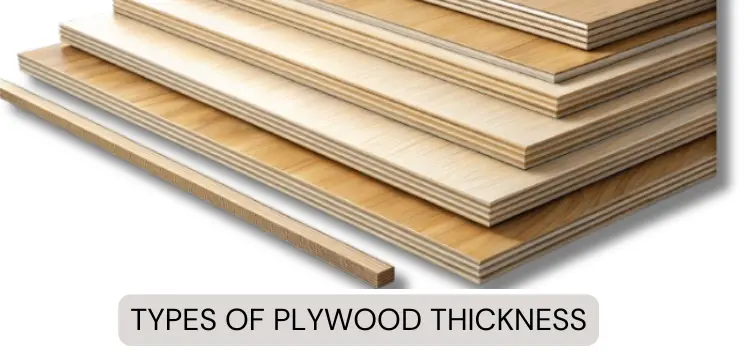

Plywood comes in various thicknesses, making it ideal for projects like furniture, flooring, and crafts. Choosing the right thickness ensures strength, flexibility, and durability. This guide explains standard plywood thicknesses and helps you pick the best option for your project needs.

Why Plywood Thickness Matters?

The thickness of plywood plays a critical role in the overall outcome of your project. The wrong thickness can result in a weakened structure or unnecessary bulk, while the right thickness ensures longevity, strength, and aesthetic appeal.

Plywood thickness directly affects the following:

- Structural Integrity: Thicker plywood can handle heavier loads and provide greater stability.

- Flexibility: Thinner plywood is more flexible, making it ideal for curved surfaces or intricate designs.

- Insulation and Soundproofing: Thicker plywood provides better insulation and sound absorption.

- Cost: Using thicker plywood unnecessarily increases project costs.

Choosing the right plywood thickness is crucial in determining how well your project holds up over time, whether you are building a bed, wardrobe, or even installing subflooring.

How To Pick Right Standard Plywood Thicknesses?

The thickness of plywood is typically measured in either inches or millimeters. Knowing the plywood thickness in mm or inches helps you select the most appropriate type for your needs.

Here’s a breakdown of the standard plywood thickness:

| Plywood Thickness (Inches) | Plywood Thickness (MM) | Common Uses |

| 1/8 | 3.2 mm | Craft projects, light decorative panels |

| 1/4 | 6 mm | Cabinet backing, drawer bottoms, light structures |

| 3/8 | 9.5 mm | Shelves, partitions, subflooring |

| 1/2 | 12.7 mm | Roofing, wall sheathing, furniture construction |

| 5/8 | 15.9 mm | Subflooring, exterior sheathing |

| 3/4 | 19 mm | Heavy-duty furniture, load-bearing walls |

| 1 | 25 mm | Structural framing, industrial use |

Different Types of Plywood Based on Thickness

Plywood thickness can vary depending on its type, manufacturing process, and intended use. Below, we explore some common types of plywood and their typical thicknesses:

1. Softwood Plywood

Softwood plywood is commonly made from pine, fir, or spruce. It’s used in structural applications like subflooring, roof decking, and wall sheathing. Softwood plywood is known for its strength and durability, making it a staple in construction.

Common thicknesses include:

- 1/4 (6 mm)

- 1/2 (12 mm)

- 5/8 (15 mm)

- 3/4 (19 mm)

2. Hardwood Plywood

Typically crafted from species like oak, birch, or maple, hardwood plywood is prized for its smooth surface and superior strength. It’s a popular choice for high-end furniture, cabinetry, and decorative projects. Hardwood plywood offers a wide range of thickness options:

- 1/8 (3.2 mm)

- 1/4 (6 mm)

- 1/2 (12 mm)

- 3/4 (19 mm)

The fine finish of hardwood plywood makes it ideal for visible areas like cabinet doors and tabletops.

3. Tropical Plywood

Known for its high quality and resistance to moisture and pests, tropical plywood is made from hardwoods sourced from tropical regions. It’s used in regions with high humidity due to its durability. Typical thicknesses include:

- 1/4 (6 mm)

- 1/2 (12 mm)

- 3/4 (19 mm)

This type of plywood is more expensive but highly valued for outdoor projects in harsh weather conditions.

4. Marine Plywood

Designed specifically for environments exposed to moisture, marine plywood is essential for boat building and exterior construction. It features waterproof adhesives and solid veneers to resist water damage. Common thicknesses for marine plywood include:

- 1/4 (6 mm)

- 1/2 (12 mm)

- 3/4 (19 mm)

Though pricier, marine plywood is unbeatable in terms of water resistance and strength for outdoor projects.

Plywood Thickness For Specific Applications

The thickness of plywood plays a crucial role depending on the project. Here’s a guide to help you choose the best plywood thickness for various common applications:

1. Plywood Thickness for Furniture Construction

For building durable furniture like tables, desks, and chairs, 3/4″ (19 mm) plywood offers the strength and stability required to support weight and withstand wear. For drawer bottoms or decorative furniture elements, thinner plywood like 1/4″ (6 mm) can be used.

2. Plywood Thickness for Wardrobe

When building a wardrobe, the thickness of the plywood plays a vital role in ensuring the structure’s stability. For wardrobe doors, 1/2″ (12 mm) or 3/4″ (19 mm) plywood provides durability and a smooth finish. For the wardrobe’s back panel, 1/4″ (6 mm) plywood is typically sufficient.

3. Plywood Thickness for Bed

The plywood thickness for a bed frame needs to offer ample support. For the slats or frame, 3/4″ (19 mm) plywood is generally recommended to ensure strength. However, for less weight-bearing parts like the headboard, 1/2″ (12 mm) may suffice.

4. Plywood Thickness for Desk

For building a desk, you want plywood that is both strong and visually appealing. A plywood thickness of 3/4″ (19 mm) is ideal for the desktop to ensure it can support the weight of items placed on it. For drawers or decorative panels, 1/4″ (6 mm) is often suitable.

5. Plywood Thickness for Subflooring

Subflooring requires plywood with sufficient thickness to support the flooring material and the load it will bear. The minimum for tile floors is 5/8″ (15 mm), though 3/4″ (19 mm) plywood is preferred for added sturdiness.

6. Plywood Thickness for Walls

For wall sheathing, plywood wall panels, or plywood partition walls, 1/2″ (12 mm) plywood is commonly used. This thickness offers enough structural support without being too bulky. In areas where strength is more critical, such as in exterior walls, you might opt for 5/8″ (15 mm) plywood.

MRS Woodcraft is a great choice if you’re looking Plywood Thickness. We offer multiple thickness options—6mm, 19mm, 25mm, and more—at affordable prices without compromising on quality. You can easily contact us on WhatsApp or fill out this form to get detailed pricing information based on the thickness you need.

Common Misconceptions About Plywood Thickness

There are several misconceptions regarding plywood thickness that can lead to poor decisions. Some of these myths include:

- Thicker is Always Better: While thicker plywood is stronger, using thicker material for light or decorative work can make your project unnecessarily bulky and expensive.

- All Plywood Is the Same: Different types of plywood, even at the same thickness, can have different performance characteristics. Always consider the type of wood, glue used, and number of plies when choosing plywood.

- Substituting Thicknesses Freely: While it may seem tempting to substitute one thickness for another, this can compromise your project’s integrity, particularly in load-bearing or structural applications.

MRS Woodcraft combines quality, durability, and sustainability, earning its place as the best plywood company in India.

Conclusion

Understanding types of plywood thickness is vital for ensuring the success of any construction or woodworking project. From furniture and cabinetry to flooring and roofing, choosing the right plywood thickness can impact strength, durability, cost, and aesthetics.

The most common thicknesses—ranging from thin sheets like 1/8″ (3.2 mm) to thick panels like 1″ (25 mm)—cover a broad spectrum of applications. With this knowledge, you can confidently choose the best plywood thickness for your specific project.

Frequently Asked Questions

What Are The Standard Thicknesses Of Plywood?

Plywood typically comes in thicknesses of 6mm, 12mm, 18mm, and 25mm.

How Do I Choose The Right Plywood Thickness?

The choice depends on the intended use, like furniture, flooring, or wall panels.

Is thicker plywood stronger?

Yes, thicker plywood generally offers better strength and durability.

Can plywood thickness vary between manufacturers?

Yes, minor variations in thickness can occur based on the manufacturer and quality.