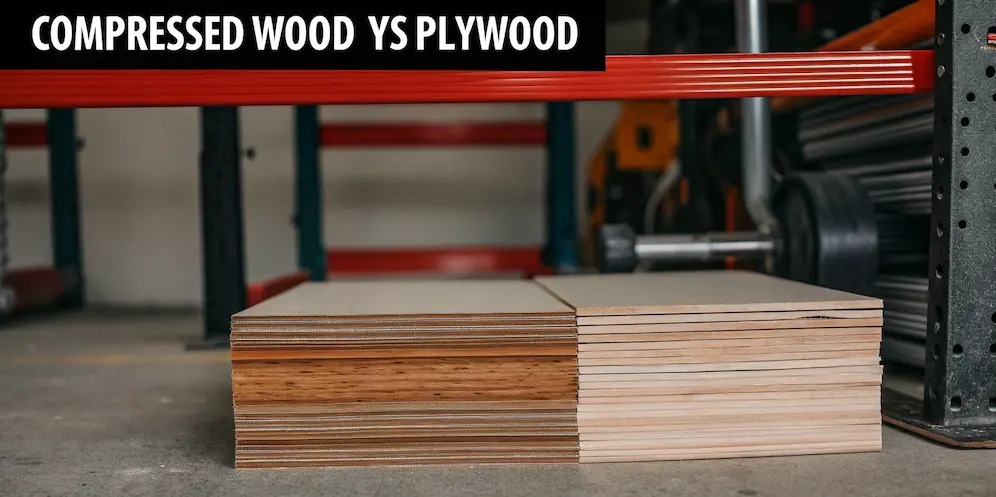

When it comes to woodworking and construction, choosing the right material is crucial. Compressed wood vs plywood is a common comparison for many projects, each offering unique benefits and applications. Both materials are used extensively in various applications as they serve different purposes and offer distinct advantages.

Understanding these aspects will enable you to select the right wood for construction or woodworking endeavors, ensuring durability, functionality, and aesthetic appeal.

What Is Compressed Wood?

Compressed wood, often high-density fiberboard (HDF) or hardboard, is created by compressing wood fibers under high pressure and temperature. Compressed wood is known for its smooth surface and durability, making it ideal for various applications. Here are the pros and cons of compressed wood:

Compressed Wood Advantages

- Density and Strength: Compressed wood is incredibly dense, providing excellent strength and durability for various uses.

- Smooth Surface: The smooth, uniform surface of compressed wood makes it ideal for painting, laminating, and other finishing processes.

- Cost-Effective: Generally more affordable than natural wood, making it a budget-friendly option for many projects.

- Environmentally Friendly: Often made from recycled wood fibers, reducing waste and promoting sustainability.

Compressed Wood Disadvantages

- Structural Limitations: While strong, compressed wood is not as structurally robust as plywood, making it less suitable for load-bearing applications.

- Moisture Sensitivity: Sensitive to swelling and damage when exposed to moisture, requiring proper sealing and maintenance.

- Weight: Compressed wood can be quite heavy, which may affect ease of handling and installation.

What Is Plywood?

Plywood is an engineered wood product made from thin layers (plies) of wood veneers glued together, with each layer’s grain oriented perpendicular to the previous layer. This cross-grain structure enhances the material’s strength and durability. Here are the pros and cons of plywood:

Advantages Of Plywood

- Structural Strength: The cross-grain construction provides superior strength and load-bearing capacity, making it ideal for structural applications.

- Versatility: Available in various grades and finishes, plywood can be used for everything from furniture to construction.

- Durability: Resistant to warping, cracking, shrinking, and interior solutions ensure long-lasting performance.

- Ease of Use: Plywood is relatively easy to work making it a favorite among DIY(Do it yourself) enthusiasts and professionals alike.

Disadvantages Of Plywood

- Cost: Generally more expensive than compressed wood, especially higher-grade plywood.

- Surface Variability: Surface quality can vary by grade, with lower grades featuring more knots and imperfections.

- Moisture Sensitivity: While more resistant than compressed wood, plywood can still be susceptible to moisture damage if not properly sealed.

Difference Between Compressed Wood vs Plywood

There are several key differences between plywood vs compressed wood, each with unique properties and applications:

1. Composition

Plywood is made of multiple layers of wood veneers glued together, with each layer’s grain alternating direction for added strength. On the other hand, compressed wood is composed of wood fibers compressed with resin binders under high pressure, resulting in a dense and uniform material.

2. Strength And Durability

Plywood offers high structural strength and excellent load-bearing capacity due to its cross-grain construction. Compressed wood, while extremely dense and durable, is not as structurally strong as plywood, making it less suitable for load-bearing applications.

3. Surface Quality

The surface quality of plywood varies by grade, ranging from smooth to rough, and can include visible wood grain and knots. Compressed wood has a very smooth and uniform surface, making it ideal for painting, laminating, and other finishing processes.

4. Applications

Plywood is versatile and used for both structural and non-structural purposes, including construction, furniture, cabinetry, and paneling. Compressed wood is primarily used for non-structural applications like furniture, cabinetry, and flooring, where a smooth finish is required.

5. Cost

Plywood is generally more expensive than compressed wood, with the price varying depending on the grade and quality. Compressed wood is typically more affordable, with the cost influenced by the type and quality of the product.

Conclusion

Choosing between compressed wood vs plywood depends on the specific needs of your project. Plywood offers superior structural strength and versatility, making it ideal for both structural and non-structural applications. Compressed wood, with its smooth surface and affordability, is perfect for non-structural uses where a high-quality finish is desired.

By understanding the differences and benefits of each material, you can make an informed decision that ensures the success of your project.

Frequently Asked Questions?

How Does Plywood Compare To Compressed Wood In Terms Of Cost?

Plywood is generally more expensive than compressed wood, especially for higher-grade plywood used for structural and high-quality applications.

What Are The Main Uses Of Plywood & Compressed Wood?

Plywood is used for structural purposes and various applications, while compressed wood is often used for non-structural projects like furniture and cabinetry where a smooth finish is desired.

Which Is More Durable, Compressed Wood Or Plywood?

Plywood is generally more durable due to its layered construction and resistance to warping and cracking

Is Compressed Wood Environmentally Friendly Compared To Plywood?

Compressed wood can be more eco-friendly because it often uses recycled wood fibers. However, plywood can also be sustainable if made from responsibly sourced wood. The environmental impact depends on the manufacturing processes of each.