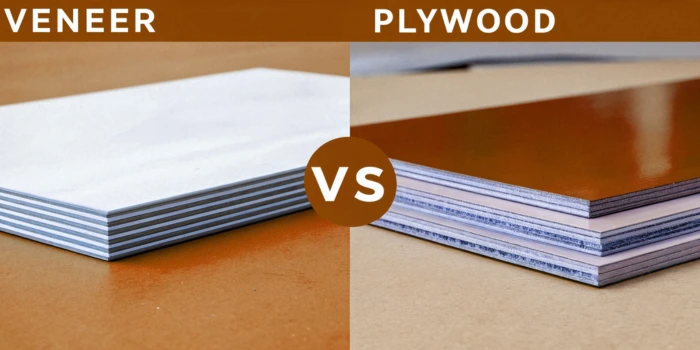

When it comes to woodworking, furniture making, and construction, both veneer and plywood are widely used materials. Although they might appear similar to the untrained eye, they are fundamentally different in terms of composition, applications, advantages, and disadvantages. Understanding the differences between veneer and plywood can help you make informed decisions when choosing the right material for your project.

Key Differences Between Veneer vs Plywood

Veneer and plywood are both wood-based materials commonly used in various industries, but they differ significantly in terms of structure, properties, applications, and cost. Here’s a table summarizing the key differences:

| Features | Veneer | Plywood |

|---|---|---|

| Composition | A thin slice of natural wood. | Multiple layers of wood veneers glued together. |

| Thickness | Typically less than 3 mm. | Varies from 3mm to over 25mm, depending on use. |

| Strength | Provides no structural strength on its own. | Strong and durable, suitable for structural applications. |

| Cost | More affordable due to less wood usage. | Generally more expensive, especially thicker grades. |

| Aesthetic Appeal | Offers the natural beauty of wood. | Can be finished with veneer for a wood-like appearance. |

| Applications | Primarily used for decorative purposes. | Used for structural and decorative purposes. |

| Durability | Can be damaged easily. | Highly durable, resistant to warping and cracking. |

| Water Resistance | Prone to water damage without additional treatment. | Varies by grade, with marine plywood offering excellent water resistance. |

| Maintenance | It requires care to avoid damage or peeling. | Low-maintenance and resistant to wear and tear. |

What Is Veneer?

Veneer is a thin layer of natural wood, typically less than 3 mm thick, that is peeled, sliced, or cut from a log. This thin sheet is then glued onto a substrate or another surface to give it the appearance of solid wood. Veneer is highly valued for its aesthetic qualities, as it retains the natural grain, texture, and beauty of the wood it is derived from.

How Is veneer Made?

The process of making veneer is a meticulous one, involving several steps to ensure that the wood maintains its natural beauty and integrity. From the selection of the raw logs to the final treatment before use, each stage plays a critical role in the production of high-quality veneer.

1. Slicing Or Peeling The Wood

Creating veneer begins with selecting high-quality hardwood logs based on their grain patterns and quality. The slicing method is used, where thin slices are cut from the log’s surface. This technique is perfect for logs with straight, uniform grains, producing veneers with a smooth, flat grain pattern. It’s favored for high-quality veneers in fine furniture and decorative applications, preserving the wood’s natural texture.

2. Drying

Once the veneer has been sliced or peeled, it must be properly dried to reduce its moisture content. This step is crucial to ensure the veneer remains stable and doesn’t warp, twist, or shrink once applied to surfaces. There are two main methods of drying veneer:

3. Finishing

After the veneer has been dried and is ready for use, it undergoes finishing treatments to enhance its appearance and prepare it for application. The finishing process may involve several steps, depending on the intended use of the veneer.

4. Grading And Sorting

After the veneer is finished, it is graded based on its quality, appearance, and defects. The grading process helps to determine how the veneer can be used and what applications it is best suited for. Higher-grade veneers are typically free of defects, with a consistent grain pattern and color, making them ideal for fine furniture or luxury items.

Applications Of Veneer

Veneer is a highly versatile material, known for its ability to replicate the appearance of solid wood while offering a more affordable and sustainable option. It is widely used in a variety of applications, including:

1. Furniture

Veneers are frequently applied to high-end furniture pieces such as tables, chairs, and cabinets. By using veneer, manufacturers can achieve the luxurious look of solid wood without the associated high cost, allowing for premium designs at a more affordable price point.

2. Cabinetry

In kitchen and bathroom cabinets, veneer is often used to create an elegant and refined finish. It provides a high-quality wood appearance while being lighter and more cost-effective than solid wood. Veneer also allows for a consistent and polished look across cabinetry.

3. Decorative Panels

Veneers are commonly used in wall cladding and partitions to add warmth and a natural aesthetic to interior spaces. The fine wood grain of the veneer gives these panels a sophisticated look, enhancing both residential and commercial environments.

4. Interior Design

From doors and tables to shelves and trim, veneers are often applied in interior design projects to give various elements a polished and luxurious finish. With a wide range of wood types and finishes available, veneer can be customized to complement different design styles, offering versatility in modern and traditional interiors.

What Is Plywood?

Plywood is a manufactured wood product made by gluing together multiple thin layers, or plies, of wood veneer. These layers are arranged with their grain direction alternating at right angles, creating a strong and durable material. Plywood is available in various grades, thicknesses, and qualities, making it suitable for a wide range of structural and decorative applications.

How Plywood Is Made?

Plywood is a popular engineered wood product made by layering thin sheets of wood veneer, bonded together with adhesive. The production process involves several steps to ensure the strength, durability, and versatility of the final product.

1. Log Processing

The process begins with selecting suitable logs, which are soaked in water or steamed to soften the wood. Once softened, the logs are peeled into thin sheets called veneers. These sheets are inspected for quality to ensure they are defect-free.

2. Layering

The veneers are then stacked in alternating layers with their grain direction alternating. This ensures the plywood’s strength and prevents warping. The number of layers can vary depending on the intended use.

3. Gluing And Pressing

Adhesive is applied between each veneer layer, and the stack is placed in a hydraulic press. The press uses heat and pressure to bond the layers together, ensuring a strong, stable structure.

4. Finishing

Once the plywood is pressed, it is trimmed, sanded, and sometimes coated with a protective finish to enhance its durability and appearance.

Common Applications Of Plywood

Plywood is highly versatile and is used in a wide range of applications due to its strength, cost-effectiveness, and ease of use.

1. Construction

Plywood is commonly used in building construction for walls, roofs, and subfloors. It provides structural support, stability, and resistance to moisture, making it ideal for these critical components.

2. Furniture

Plywood serves as a durable and affordable base for furniture. It is used to make tables, chairs, cabinets, and more. It is often finished with veneers or laminates to give it the appearance of solid wood.

3. Packaging

Plywood is used in the packaging industry for creating shipping crates, pallets, and boxes. It is strong enough to protect goods during transport and is often preferred for heavy-duty applications.

4. Marine Use

Marine-grade plywood is used in boatbuilding due to its resistance to water and rot. This type of plywood is made with high-quality veneers and waterproof adhesives, making it perfect for boats and other watercraft.

5. Flooring

Plywood is commonly used as an underlayment in flooring projects, providing a stable foundation for hardwood floors, tiles, or carpets. Its ability to withstand heavy loads and moisture makes it ideal for these applications.

Advantages Of Veneer

Veneer, made by slicing thin sheets of wood from logs, offers several advantages over solid wood and other materials. Here are some key benefits:

1. Cost-Effective

Veneer allows manufacturers to create the appearance of solid wood at a much lower cost. By using a thin layer of high-quality wood over a cheaper substrate, veneer enables businesses and consumers to enjoy the aesthetic appeal of wood without the expensive price tag.

2. Aesthetic Appeal

Veneer showcases the natural beauty of wood, with unique grain patterns, textures, and color variations. It provides a high-end look and is often used in luxury furniture, cabinetry, and interior finishes. Veneers can be applied to a variety of substrates, such as plywood or MDF, offering design flexibility.

3. Sustainability

Since veneer is made from thin slices of wood, it maximizes the use of timber. The process helps reduce waste by allowing a single log to produce many sheets of veneer. This makes veneer a more sustainable option compared to using solid wood for large surfaces or furniture.

4. Lightweight

Veneer is much lighter than solid wood, making it easier to handle and install. This can be particularly advantageous in applications such as furniture, wall cladding, and cabinets, where weight could otherwise be a concern.

5. Resistant To Warping

Due to its thinness and the way it’s processed, veneer is less likely to warp, crack, or shrink compared to solid wood. This makes it a more stable option, particularly in applications where the material may be exposed to temperature or humidity fluctuations.

6. Versatility In Design

Veneer can be applied to a variety of substrates, including plywood, MDF, and particleboard, allowing for flexibility in design and construction. It can also be stained or finished to mimic a wide range of wood species, providing more design options without the need for solid wood.

Veneer is a versatile and sustainable material that offers a combination of affordability, aesthetic appeal, and durability, making it an excellent choice for various applications in furniture, cabinetry, and interior design.

Advantages Of Plywood

Plywood is a widely used material known for its versatility, durability, and strength. Here are some key advantages of plywood:

1. Strength And Durability

Plywood is renowned for its strength and durability. The alternating grain pattern of its layers gives it superior strength and resistance to bending, warping, or cracking, making it ideal for structural applications like walls, floors, and roofs.

2. Cost-Effective

Compared to solid wood, plywood is more affordable while offering many of the same aesthetic and functional qualities. This makes it a budget-friendly choice for construction, furniture, and other applications where solid wood might be too expensive.

3. Lightweight

Despite its strength, plywood is lightweight, which makes it easier to handle, transport, and install. Its reduced weight can be particularly advantageous for furniture, cabinetry, and flooring projects, as it reduces the overall load and makes construction simpler.

4. Versatility

Plywood can be used in a wide range of applications, from construction and furniture making to cabinetry, packaging, and marine use. It comes in various grades and thicknesses, making it adaptable for different purposes and customizable to fit specific needs.

5. Environmental Benefits

Plywood is made from multiple layers of wood, maximizing the use of timber and minimizing waste. It is also available in eco-friendly options, such as plywood made from sustainably sourced wood, making it a greener alternative to solid wood in many cases.

6. Resistance To Shrinking And Warping

Plywood is less likely to shrink, swell, or warp compared to solid wood. This makes it a more stable option for applications that are exposed to varying temperatures and humidity levels, such as subfloors, ceilings, and exterior sheathing.

Plywood’s strength, cost-effectiveness, versatility, and ease of use make it a popular choice in various industries, from construction to furniture making and beyond. It offers a range of benefits that make it both a practical and sustainable material for many applications.

When To Choose Veneer?

Choose veneer when you prioritize aesthetic appeal and want the look of natural wood at a lower cost. It’s ideal for decorative projects where structural strength isn’t a primary concern.

- Aesthetic Appeal is a Priority: If you’re looking for the natural beauty of wood without the high cost, veneer is an excellent choice. It offers a high-end look with its distinct grain patterns, rich textures, and variety of finishes.

- Decorative or Non-Structural Projects: Veneer is ideal for decorative applications like furniture, wall cladding, and cabinetry, where the visual appearance matters more than structural strength. It works well for surfaces that don’t bear heavy loads.

- Cost-Effectiveness: If you’re working on a budget but still want the elegance of wood, veneer provides a cost-effective alternative to solid wood. You can achieve the look of solid wood at a fraction of the price by using veneer on a less expensive substrate like plywood or MDF.

Veneer is a great solution for adding elegance and beauty to your project without the expense or weight of solid wood.

When To Choose Plywood?

Choose plywood when you need strength, durability, and stability for construction or heavy-duty furniture. It’s perfect for applications requiring versatility, multiple thickness options, and long-lasting performance.

- Strength and Durability Are Critical: Plywood is known for its exceptional strength, thanks to its layered construction. If your project requires material that can handle heavy loads, resist warping, and withstand harsh conditions, plywood is the ideal choice. It’s especially suitable for structural applications like flooring, walls, and roofing.

- Heavy-Duty Furniture or Construction: When building heavy-duty furniture or engaging in construction, plywood’s robust nature makes it the perfect option. It’s used extensively for cabinets, tables, shelving units, and other furniture pieces that require stability and longevity.

- Versatility in Applications and Thickness Options: Plywood comes in a wide variety of thicknesses and grades, giving you the flexibility to choose the right material for your specific needs. Whether it’s for interior design, cabinetry, marine use, or general construction, plywood offers versatility and customization.

Plywood is a great choice when your project demands strength, durability, and adaptability across various applications, from construction to furniture-making.

Conclusion

Veneer and plywood complement each other in woodworking. Veneers provide aesthetics, while plywood offers strength. Combining them ensures durability and beauty. Whether you’re refurbishing a particle board cupboard or creating custom furniture, using plywood & veneers from trusted sources like MRS Woodcraft ensures excellent results.

Frequently Asked Questions

Is plywood waterproof?

Most standard plywood is not waterproof, but marine-grade plywood or treated plywood is designed to resist water exposure.

Can Wood Veneer Be Sanded?

Yes, but with caution. Use fine-grit sandpaper and light pressure to avoid damaging the thin veneer layer.

How Do You Maintain Veneer Surface?

Clean gently with a soft cloth and mild soap. Avoid abrasive cleaners and excessive water to preserve the finish.

What Is The Lifespan Of Plywood Furniture?

With proper care and depending on the plywood grade, it can last 10-20 years or more.