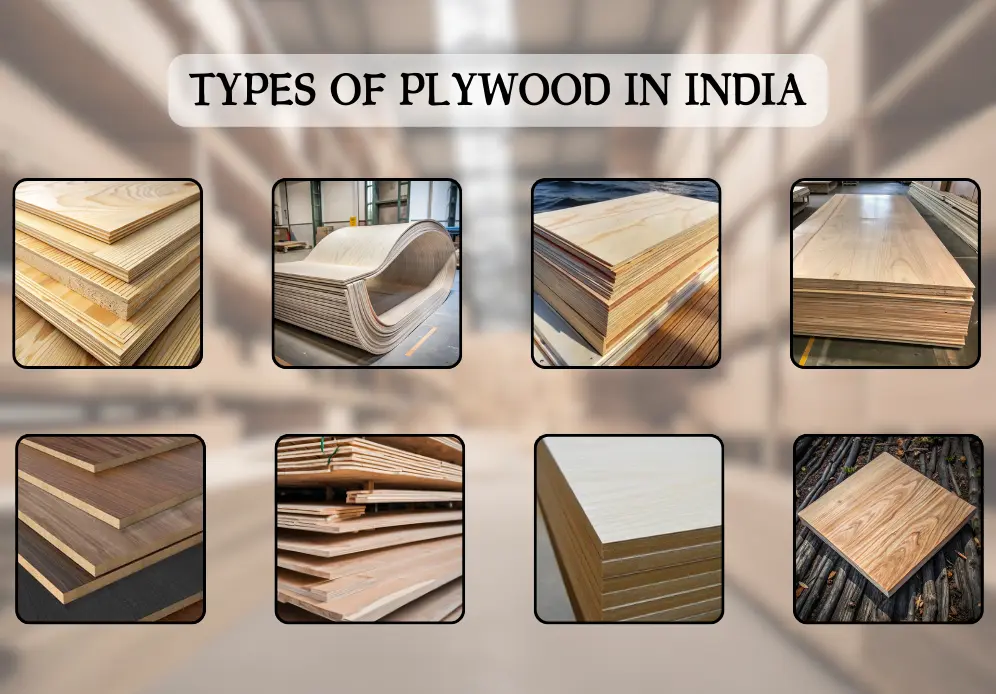

Plywood is a versatile and essential material used in a range of applications, from furniture making to construction. In India, where the demand for quality plywood is high due to rapid urbanization and infrastructural development, understanding the various types of plywood available can help consumers and builders make informed decisions.

This article explores the different types of plywood in India, their characteristics, and their applications, providing valuable insights for anyone looking to choose the right plywood for their needs.

What Is Plywood?

Plywood is an engineered wood product composed of plies, which are thin wood veneer layers bonded together in a cross-grain pattern. This construction technique enhances the strength and stability of the material, making it ideal for various uses.

The quality and type of plywood depend on the species of wood used, the adhesive used for bonding, and the number of layers in the product.

Types Of Plywood In India

When exploring the different types of plywood available in India, it’s essential to understand their unique properties and uses. Each type serves specific purposes, from general interior work to high-moisture environments. Knowing the characteristics of each variety will guide you in selecting the right plywood for your project.

1. Commercial Plywood

Characteristics

Plywood is made from softwood veneers and bonded with phenolic or urea-formaldehyde adhesives known as commercial plywood, offering moderate resistance to moisture and environmental changes. Commercial plywood, often referred to as MR (moisture-resistant) grade plywood, is widely used for general-purpose applications

Applications

- Furniture: Ideal for making cabinets, tables, and chairs.

- Interior Wall Panels: Used for decorative purposes and internal partitioning.

2. Marine Plywood

Characteristics

Marine plywood is specifically designed to withstand high moisture environments. It is made from durable hardwood veneers and bonded with a waterproof adhesive. Its high resistance to water and termites makes it suitable for use in marine and coastal areas.

Applications

- Boat Building: Used in the construction of boats and ships.

- Outdoor Furniture: Suitable for garden furniture and outdoor applications.

3. BWR Plywood

Characteristics

Hardwood veneers, bonded with phenolic resins, making them highly durable and moisture-resistant is BWR plywood. BWR (boiling water resistant) plywood is engineered to resist boiling water and extreme weather conditions.

Applications

- Kitchen Cabinets: Ideal for use in kitchens where exposure to water and steam is frequent.

- Bathroom Fixtures: Used in bathrooms where moisture resistance is crucial.

4. Blockboard

Characteristics

The blockboard is made from a core of softwood blocks sandwiched between two layers of plywood. It offers good strength and is lighter compared to traditional plywood. The outer layers are often made from high-quality veneer.

Applications

- Partition Panels: Used for interior partitioning in offices and homes.

- Furniture: Suitable for making doors and cabinets.

5. Flush Doors

Characteristics

Flush doors are a type of plywood used primarily for doors. They consist of a solid core encased in a veneer or plywood face. These doors are known for their smooth finish and durability.

Applications

- Interior Doors: Commonly used for residential and commercial interior doors.

- Fire Doors: Specially treated flush doors can be used as fire-resistant doors.

6. Film-Faced Plywood

Characteristics

Film-faced plywood is coated with a film to enhance its durability and water resistance. It is commonly used in construction and formwork due to its ability to withstand harsh conditions.

Applications

- Concrete Formwork: Used for constructing concrete molds and formwork.

- Construction Scaffolding: Ideal for scaffolding structures due to its strength.

Factors To Consider When Choosing Plywood

Consider the following aspects while choosing plywood:

1. Purpose of Use

Determine the primary application of the plywood. For example, marine plywood is best for outdoor and water-exposed areas, while commercial plywood is suited for indoor furniture.

2. Moisture Resistance

Choose the grade of plywood based on the moisture levels it will be exposed to. MR grade is suitable for moderate moisture, while BWR and marine plywood offer higher resistance.

3. Strength and Durability

Analyze the strength required for your application. For structural uses, such as formwork or heavy furniture, opt for high-grade plywood with strong adhesive bonding.

4. Cost

Plywood prices vary based on type and quality. While marine and BWR plywood are more expensive due to their enhanced properties, commercial and blockboard plywood offer cost-effective solutions for less demanding applications.

5. Finish and Aesthetics

Consider the finish and appearance of the plywood. Veneered plywood offers a polished look suitable for visible surfaces, while film-faced plywood is more utilitarian.

Conclusion

Choosing the right type of plywood is crucial for ensuring the longevity and functionality of your project. Understanding the various types of plywood available in India such as commercial, marine, BWR, blockboard, flush doors, and film-faced plywood can help you make an informed decision based on your specific needs.

By considering factors such as moisture resistance, strength, and cost, you can select the most suitable plywood for your project and achieve the best results. Whether you are building furniture, constructing formwork, or designing indoor spaces, the right plywood will enhance the quality and durability of your work.

Frequently Asked Questions (FAQs)

1. What Is The Difference Between MR And BWR Plywood?

MR (moisture-resistant) plywood offers basic resistance to moisture and is suitable for indoor applications. BWR (Boiling Water Resistant) plywood, on the other hand, is highly resistant to boiling water and extreme weather conditions, making it ideal for areas with high moisture exposure.

2. Can Marine Plywood Be Used For Indoor Furniture?

Yes, marine plywood can be used for indoor furniture, but it is more expensive compared to other types. It is primarily designed for high-moisture environments, so its use in indoor applications might be excessive unless additional durability is required.

3. How Do I Choose The Right Plywood For My Project?

Consider factors such as the purpose of use, moisture resistance, strength, cost, and finish. For example, use marine plywood for outdoor or water-exposed areas and commercial plywood for general indoor applications.

4. What Is Blockboard And How Is It Different From Plywood?

The blockboard consists of a core of softwood blocks between two layers of plywood. It is lighter and offers good strength for specific applications like partitions and doors, whereas plywood is made from thin layers of veneer glued together.

5. Is Film-Faced Plywood Suitable For Residential Use?

Film-faced plywood is primarily used for construction and formwork due to its durability and water resistance. While it can be used for residential applications, it is typically chosen for its strength rather than aesthetic purposes.